It’s no secret that the larger a space is, the harder it is to heat, and nowhere is this truer than in a warehouse’s high ceilings and poor insulation. Plus, with frequent movement of goods and personnel, heat is constantly escaping, meaning cold spots are rampant.

Traditional heating systems often struggle to distribute heat efficiently, leaving workers, products, and materials vulnerable to uncomfortable or even damaging conditions. From towering shelves to vast open layouts, warehouses are tailor-made for productivity, not necessarily for consistent heating. That’s why this article will discuss why infrared heaters are perfect for warehouses and how they can reduce cold spots.

The Challenges of Heating Warehouses

Large Open Spaces

The sheer size of warehouses makes it incredibly difficult for traditional heating systems to maintain even warmth throughout the facility. With expansive floor areas and minimal interior walls, heat often dissipates quickly, leaving some sections warmer than others. This uneven heat distribution results in inconsistent temperatures that are hard to regulate effectively.

High Ceilings and Air Stratification

Warehouses often have high ceilings, creating a perfect environment for air stratification. Warm air tends to rise and collect near the ceiling, while colder air remains at ground level where workers typically operate. This natural phenomenon makes it challenging for standard heating systems to distribute heat properly, leaving employees and equipment in lower areas exposed to the cold.

Frequent Door Openings

The continuous movement of goods and personnel means workers frequently open and close warehouse doors, allowing cold air to rush in and warm air to escape. This constant exchange of air not only makes it difficult to maintain a stable temperature but also exacerbates the challenges of keeping the space warm and energy efficient.

Energy Costs

Heating a warehouse with traditional systems can lead to significant energy inefficiencies and high operating costs. Conventional systems often require prolonged operation to combat heat loss and maintain a uniform temperature. This can quickly add up in terms of energy usage, making these systems expensive solutions for large-scale facilities.

Cold Spots

Cold spots are a common issue in warehouses, particularly in areas far from heating units or those with poor airflow. Unevenly heated spaces can create discomfort for staff, reduce productivity, and even pose risks to temperature-sensitive inventory such as food, pharmaceuticals, or other delicate materials. Addressing cold spots is critical not only to ensure a comfortable and efficient working environment but also to avoid damaging precious stock.

How Infrared Heaters Work

Infrared heaters operate by emitting radiant heat, which warms objects and surfaces directly instead of solely heating the surrounding air. This mechanism mimics the way the sun heats the Earth, as the infrared radiation transfers energy to objects it encounters, causing them to warm up. This approach is more energy efficient than conventional heating methods because it minimizes heat loss and provides faster, localized warmth.

Targeted Heating

One of the primary benefits of infrared heaters is their ability to focus heat on specific areas. This makes them particularly effective for addressing cold spots in warehouses, where you can strategically position them to target areas requiring additional warmth. By providing direct, concentrated heat, these heaters ensure a more consistent temperature across the facility, enhancing comfort and productivity.

Types of Infrared Heaters

There are two main types of infrared heaters—gas-powered and electric. Gas-powered heaters are ideal for large spaces, as they can produce significant heat output and are often more cost efficient for extended use.

Electric infrared heaters, on the other hand, are easy to install and operate, offering a cleaner and quieter solution. However, they’re not as effective for larger spaces; just be sure to take into account the needs of your facility, including size, layout, and energy sources available.

Benefits of Infrared Heaters in Reducing Cold Spots

Direct and Efficient Heat Delivery

Unlike traditional heating systems, which can lose significant heat as warm air rises or disperses, infrared heaters focus their energy where you need it most. This precision minimizes energy loss and ensures that even the coldest areas are warmed effectively, making them powerful tools for tackling those stubborn cold spots.

Quick Heat-up Time

One of the standout features of infrared heaters is their ability to provide almost instant warmth. Traditional forced-air systems can take time to circulate heated air through a space, but infrared heaters begin warming problem areas immediately. This rapid response time makes them incredibly effective for targeted use, whether it’s a chilly warehouse corner or a workstation subjected to drafts.

Improved Temperature Uniformity

Infrared heaters excel at reducing temperature stratification, the uneven layering of warm air near the ceiling and cooler air near the floor. By directly warming objects and surfaces, these heaters keep heat closer to the floor, where it benefits employees and equipment the most. This results in a more consistent and comfortable temperature throughout the facility, eliminating frustrating cold spots.

Energy Efficiency

Infrared heaters are not only effective but also cost-efficient. By focusing heat delivery directly where it’s required, these systems avoid the energy waste associated with heating large volumes of air. Compared to conventional forced-air systems, infrared heating can lead to significant energy savings, helping businesses lower their operating costs while staying warm.

Enhanced Worker Comfort

Comfortable employees are more productive employees. Infrared heaters ensure that workspaces remain consistently warm, even during the coldest months. This reduces complaints about drafts or chilly areas and boosts morale and productivity. A comfortable environment fosters greater employee satisfaction, ensuring everyone stays focused and engaged.

Protection for Equipment and Inventory

Extreme cold can have serious consequences for machinery and inventory. Infrared heaters safeguard sensitive equipment by maintaining consistent temperatures and preventing damage caused by freezing conditions. Additionally, inventory items that are sensitive to temperature fluctuations, like liquids or delicate materials, benefit from the stable warmth these heaters provide. This added protection helps businesses avoid costly repairs or product losses.

With infrared heaters, it’s easy to combat cold spots in your warehouse and protect your workers and products. Whether you’re looking to boost productivity or safeguard materials, infrared heating is the modern solution your warehouse has been waiting for.

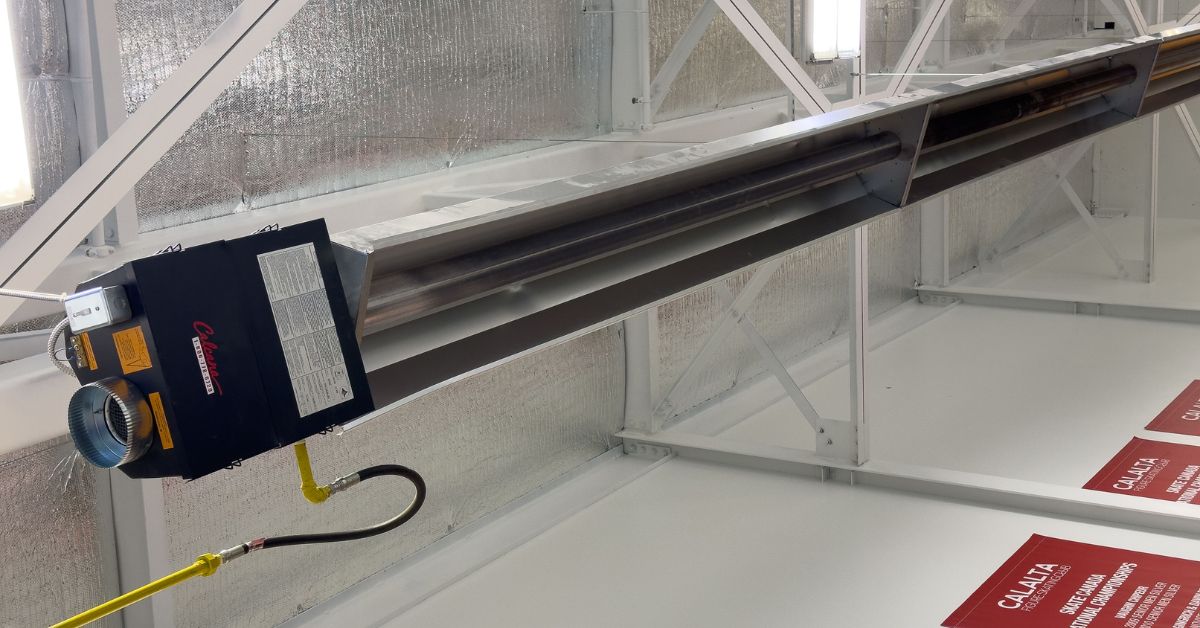

At Calcana, our ceiling-mounted industrial infrared heaters not only save space but also provide highly efficient heating for large open spaces, making them the perfect choice for warehouses. Experience the difference in comfort and energy savings with our advanced infrared heating technology.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.